How good is your replenishment?

Chances are that, in spite of all the efforts calculating forecasts and all the time listening to salespeople, customers and your operations staff, you still have too many shortages coupled with too many surplus. Maybe it is time you check your assumptions.

There is only one direct cause

Daily decisions of how much to replenish of each item at each location is what produces the inventories you currently have.

Decisions are made based on a set of assumptions.

If you are not happy with the results, stop improving the current actions and examine the assumptions on which you base your decisions.

A couple of hints

Forecasts (as used by the vast majority of companies) produce errors that are way beyond the limits that both space or cash can tolerate. No matter how good you think your forecast is, we bet you end up with shortages and surplus.

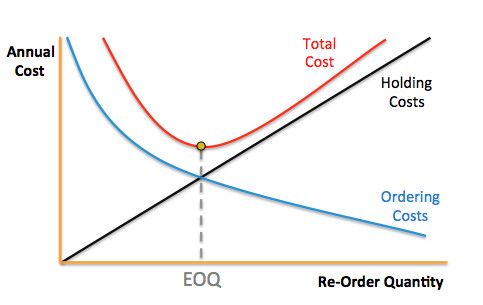

Reorder point or MIN/MAX, coupled with EOQ (economic order quantity) are vastly popular methods to manage inventories. We can easily demonstrate that those methods lead to inventory levels inherently mistaken.

There is a much better way

Theory of Constraints (TOC) was invented by Dr. Goldratt, a physicist. As a scientist, Dr. Goldratt studied supply chains, got a deep understanding of the system, with all the variability and complexity, and developed a simple, effective and robust solution.

Thousands of companies have implemented these ideas enjoying less inventories with availability of items on the high nineties(over 97-99%).

FILLRATE100 is an implementation of these ideas.

What can FILLRATE100 do?

Simply put: it decides how much of each item to replenish at each location of your supply chain.

If it is only central warehouse or you have a complex network of warehouses and points of sale, FILLRATE100 will tell you everyday exactly what to do.

It has an intelligent engine to follow the trends of actual demand, making the decision in order to minimize inventories and ensure 100% fill rate.

It can be operated semi-automatic or fully integrated with your system, both ERP or legacy or self developed, even if it is a worksheet.

We are here to help you

One of our partners in the world can guide you from setting the initial parameters all the way through the process of going live in less than a week. In fact, you can have your first list of replenishment orders in one or two days.